News

The Fenzi Group strengthens its commitment to a more sustainable future

March 2025

As part of the sustainable business development projects defined by the Fenzi Green Future Action Plan, the Fenzi Group reinforces its commitment by announcing the achievement of Environmental Product Declarations (EPD) for its entire range of sealants for IG Units.

These documents, known as EPDs (Environmental Product Declarations), are voluntary environmental declarations verified by an accredited third-party body. They are applicable to any type of product or service and are based on international standards. Through EPDs, the environmental impact of a specific product or service can be described in a transparent, objective, and comparable way using the Life Cycle Assessment (LCA) of the product.

The LCA is the most structured, comprehensive, and internationally standardized method for assessing the environmental impact of products and systems. It considers the entire life cycle, from upstream stages (pre-production), through the core stage (production), to downstream stages (installation, use, maintenance, recovery, disposal).

While EPD certification is voluntary, an increasing number of companies are choosing to obtain it because of its benefits to producers, distributors, and consumers, especially in terms of environmental communication.

Furthermore, EPDs play a key role in developing GREEN BUILDING by contributing to obtaining credits that are valid for:

- The evaluation of CAM (Minimum Environmental Criteria)

- LEED certifications (in Energy and Environmental Design)

- GBC Italia UNI / PdR 13.1: 2015 protocols, known as the ITACA and BREEAM protocols (Building Research Establishment Environmental Assessment Method).

Detailed Look at FENZI's EPDs

Published in July on the leading platform, EPD International, the Fenzi EPDs were developed in compliance with UNI EN ISO 14045 standards and PCR 2019:14, specific to construction products.

The data collection phase, coordinated by Fenzi Group's ESG Department, involved the direct participation of three European production sites: Tribiano (MI) in Italy, Vilvoorde in Belgium, and Jaworzno in Poland.

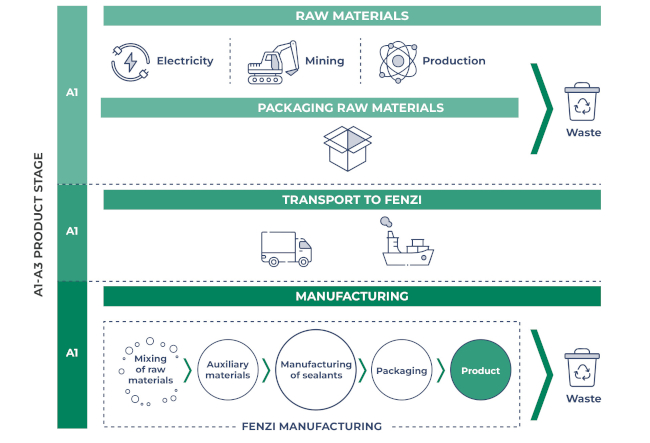

The LCA analysis followed a Cradle-to-Gate with Modules C1-C4 and Module D approach (A1–A3 + C + D). This analysis assesses the life cycle of Fenzi products from raw material extraction and production ("cradle") to the factory gate (i.e., before transportation to the customer), including the packaging of the finished product and an end-of-life evaluation. Distribution, installation, and product use stages were excluded from this analysis.

The chosen declared unit for the EPD is 1 kg of product.

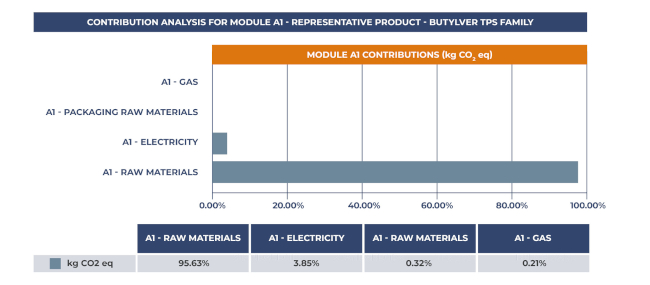

Within phases A1-A3, data was analyzed for raw material extraction, electricity production, natural gas consumption, waste generation, emissions, packaging use, the sealant production cycle, and material transportation to production sites.

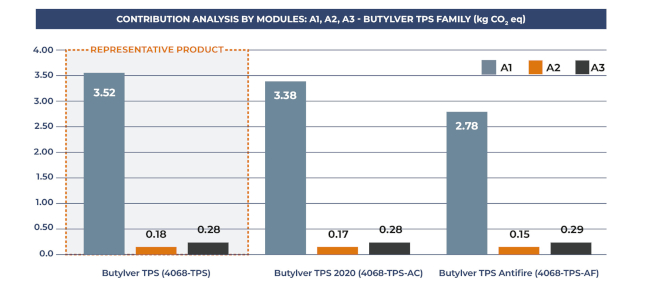

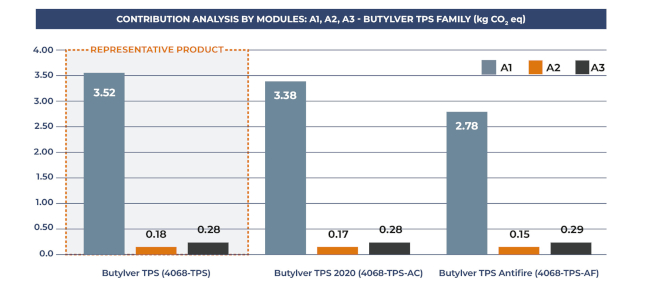

Subsequently, based on sales volume, the most representative product was selected for each product family: Butylver TPS, Butylver, Hotver, Thiover, Thiover Hardener, Poliver, and Poliver Hardener.

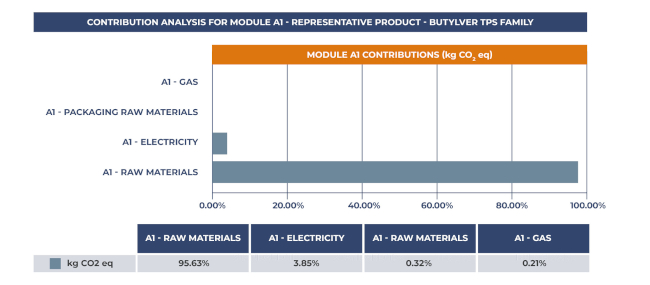

An analysis of the results reveals that across all impact categories, the primary contributions stem from Upstream processes (A1), especially those related to raw material sourcing.

As an example, the following charts provide insights into Butylver TPS:

This accomplishment not only reinforces our commitment to minimizing environmental impact but also offers our customers transparent, verified insights into the ecological performance of our products.

We look forward to continued innovation and collaboration with all of you as we work toward a more sustainable future.